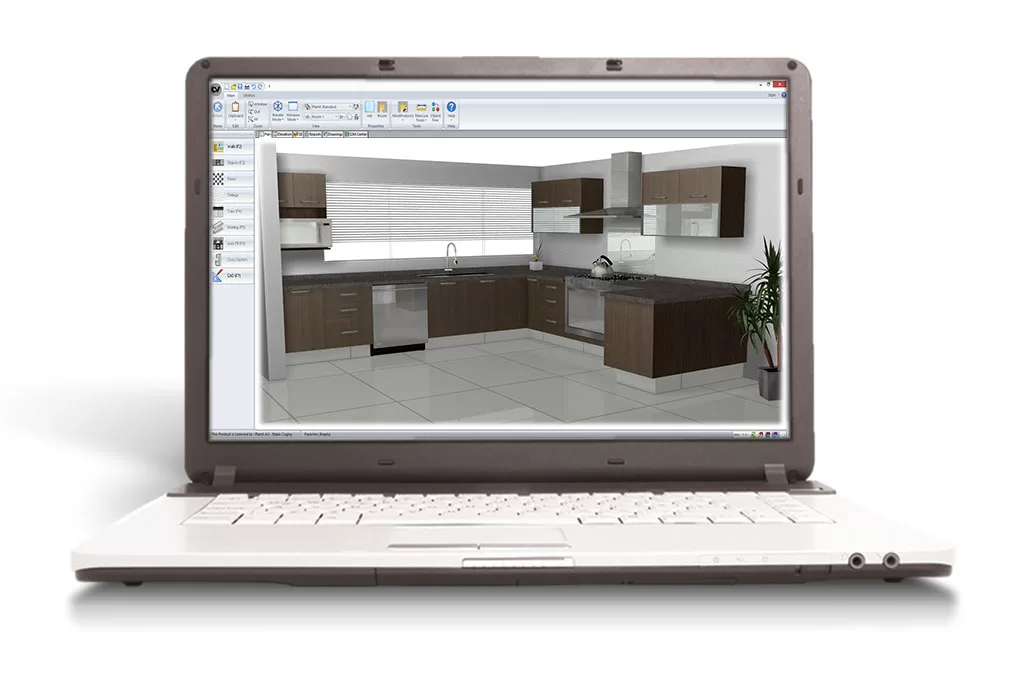

The development of CAD software in the kitchen and bathroom industry has changed how many designers and cabinet makers operate. Long gone are the days of hand drawing a quick sketch of a design and trying to use it to get the sale.

In today’s environment, consumers demand more – more communication, more knowledge and more understanding. CAD software supplies an in-depth ability to communicate clearly and accurately with your clients, helping them to understand the intricacies of the design and how the finished product will look in a far more realistic way.

In today’s environment, consumers demand more – more communication, more knowledge and more understanding. CAD software supplies an in-depth ability to communicate clearly and accurately with your clients, helping them to understand the intricacies of the design and how the finished product will look in a far more realistic way.

Because this area is so important, TKBB asked leading provider of software to the kitchen and bathroom industry, Planit Cutting Edge Solutions, to share their top five reasons CAD software is important for your business.

Because this area is so important, TKBB asked leading provider of software to the kitchen and bathroom industry, Planit Cutting Edge Solutions, to share their top five reasons CAD software is important for your business.

- 3D Photo-realistic renders – Consumers need to visualise their design. They want to get a real-life representation of how their kitchen or bathroom will look before they sign off on the final design. As renders in CAD Software continue to improve, light, shadow, colour, texture and depth help the finished design look more realistic.

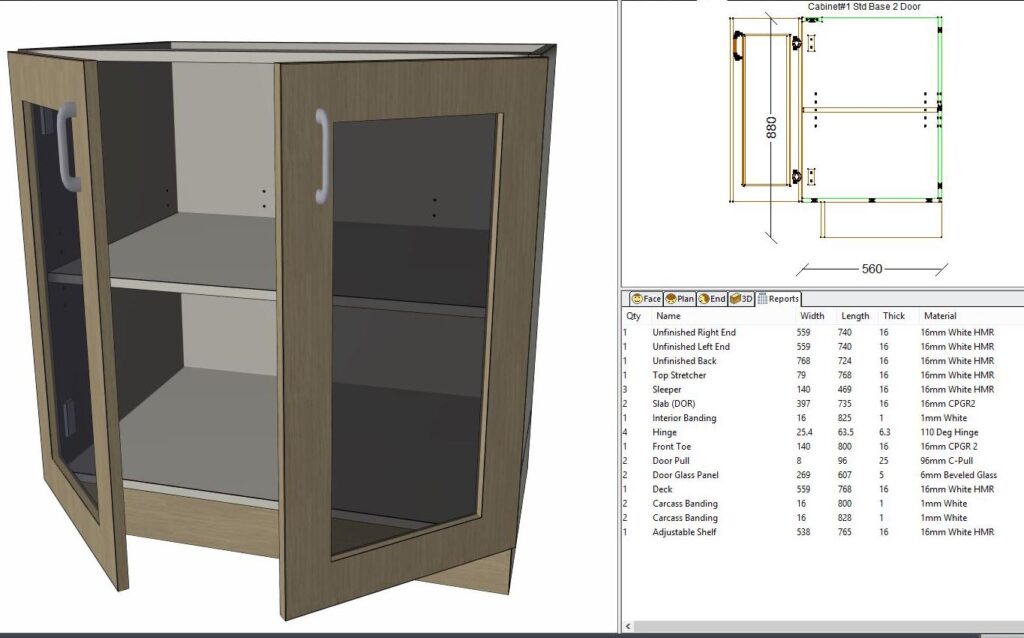

- Quoting –Quoting accurately is essential to ensuring you are competitive. CAD software can be set up to factor in materials, hardware, labour, overheads and mark ups to provide an accurate price to present to your customer.

- Quick modifications – CAD software makes it simple and easy to make adjustments to the design based on feedback from the customer. You can easily change cabinet types and sizes, materials, hardware, etc. No longer do you need to redraw the whole design again just for a few small changes.

- Automation makes your life easier – Software is designed to automate more processes, increase accuracy and maintain consistency. Once accuracy, ease of change, quoting and reporting are taken into consideration, the “old way”, although familiar, can be very unproductive. The results and benefits of using software speak for themselves. Companies have been able to cut design time in half thanks to the use of software.

- It’s the beginning of production – The concept of “Design-to-Manufacture” means a design can be sent straight to the factory and CNC Machine. What you’ve designed is what is sent to production and you are able to see exactly how the cabinetry will look before it’s machined. If you outsource your manufacturing it’s simple and easy to share your design files.

For more information visit www.au.planit.com

For more information visit www.au.planit.com